TÜV AUSTRIA ensures safety at this unique demonstration plant for the storage of green hydrogen.

In this lead project, renewable solar energy is converted into green hydrogen in a climate-neutral way by means of electrolysis and stored in a pure form in former natural gas deposits. The scale of the storage corresponds to the summer surplus of about 1,000 photovoltaic systems on single-family homes or 4.2 million kWh (4.2 GWh). In summer, this surplus energy is stored and in winter the green energy can be provided again in the form of electricity and heat.

Plant operator RAG AUSTRIA AG has been a customer of TÜV AUSTRIA for many years and also relies on reliable quality and safety for the future-oriented project “Underground Sun Storage 2030” (USS 2030) and commissions TÜV AUSTRIA with the acceptance test of the plant. “For RAG AUSTRIA AG, the cooperation with TÜV AUSTRIA is essential in order to guarantee the required highest safety standards. The special requirements in this project were fulfilled by the TÜV AUSTRIA specialists in a proven manner, competently and flexibly, to our complete satisfaction”. Werner Bogner, Team Leader Renewables & Decarbonisation / Green Gas Technology Department, summarises the cooperation.

Around two years after the start of the project, the system and storage tank of “Underground Sun Storage” were inspected with regard to electrical, pressure and control technology. TÜV AUSTRIA experts Ing. Daniel Wetsch, Dipl.-Ing. (FH) Florian Rainer and Dipl.-Ing. Oliver Lugmayr carried out the electrical system inspection and machine safety inspection on site. It was ensured that the machines comply with the requirements of the Machinery Directive (2006/42/EC) and, with regard to the electrical equipment, with the EN 60204 standard. Furthermore, TÜV AUSTRIA test engineer Dipl.-Ing. Leonhard Hofer checked the functional safety and engineer Dietmar Heimberger inspected the system with regard to pressure equipment aspects.

Targeting expertise in dealing with hydrogen

During the acceptance test, special attention had to be paid to the property of hydrogen as an extremely volatile element. This had to be taken into account especially during the pressure equipment test, as it had to be ensured that all seals and connection components, in particular, not only withstand the necessary high pressure – tested at up to 90 bar – but also do so in combination with H2. But also with regard to the avoidance of explosion hazards, the volatility of hydrogen had to be carefully considered. One focus of the inspection was on the machine in which the electrolysis, i.e. the conversion of water into hydrogen, takes place, in order to rule out the possibility of an H2 atmosphere developing here.

In this research project, interdisciplinary technical-scientific investigations for energy storage under real conditions are being carried out at a small former natural gas deposit in the municipality of Gampern (Upper Austria) under the leadership of RAG AUSTRIA AG together with the project partners. The aim is to jointly gain valuable technical and economic knowledge for the development of a secure hydrogen supply.

TÜV AUSTRIA’s expertise in hydrogen was put to optimal use in this project and makes an important contribution to the energy transition while maintaining security of supply.

TÜV TRUST IT TÜV AUSTRIA GMBH

Kick-off: Cybersecurity Center at the TU Vienna

Exciting exchange at panel discussion

At the opening event of the cross-faculty center of the Vienna University of Technology on April 18, 2024, researchers, practitioners and decision-makers came together to promote cooperation and knowledge exchange in order to meet the challenges of cybersecurity at both local and global level.

During the panel discussion, the participants – including Andreas Köberl (TÜV TRUST IT TÜV AUSTRIA GMBH) – emphasized, among other things, the role of universities in transferring knowledge about cybersecurity to industry and the public sector. An interdisciplinary strategy should close gaps in understanding and application and strengthen resilience against cyber threats.

Cooperation

SIListra Systems GmbH, a highly specialized software company, and innotec GmbH, a consulting company specialized in Functional Safety, announced their strategic partnership to improve the safety development of embedded systems. The collaboration brings together SIListra’s cutting-edge software tool, the certified SIListra Safety Transformer, and innotec expertise in functional safety solutions, aiming for a holistic approach to functional safety.

EU AI Act

Closing regulatory gaps quickly

TÜV AUSTRIA published position paper

TÜV AUSTRIA presents requirements and proposed solutions for the assessment of AI systems, recommends a corresponding clarification for the EU AI Act and published a position paper.

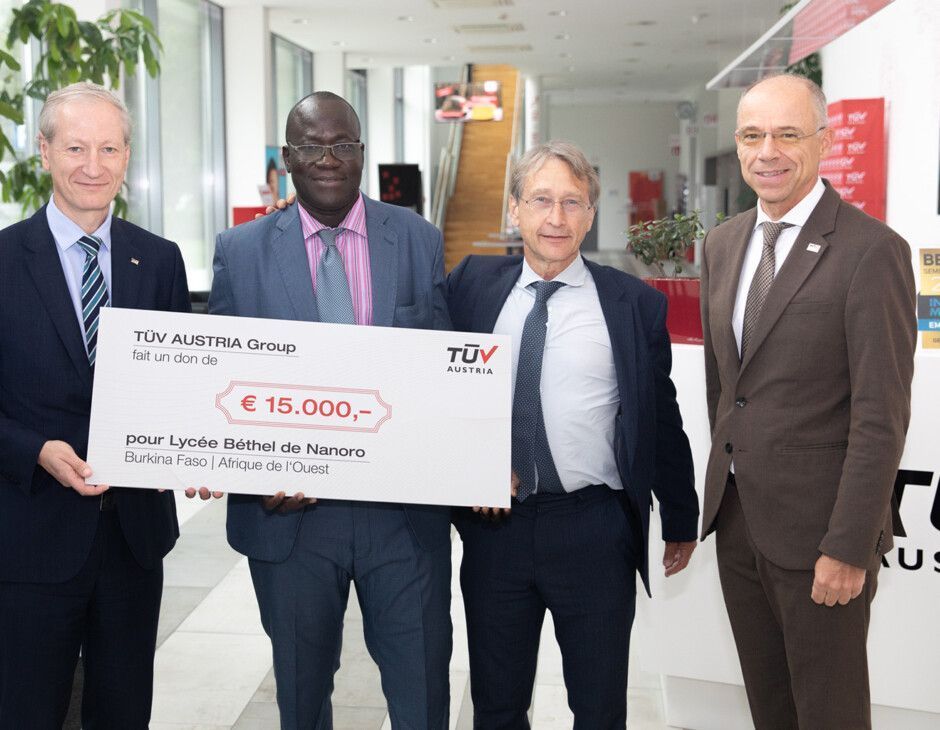

TÜV AUSTRIA supports Burkina Faso school project

Project Nanoro

Bethel High School Opening in Sight

Three years after the start of construction, the Nanoro project is nearing completion. The buildings have been erected, the photovoltaic system has been installed, and in October Bethel High School will open its doors to the first 300 students. TÜV AUSTRIA has been supporting the project since 2019.

TRUSTIFAI

The Seal of Quality for Artificial Intelligence

Austria’s first AI testing and qualification hub

TÜV AUSTRIA and the Software Competence Center Hagenberg (SCCH) announced the founding of Austria’s first AI testing and qualification hub at a press conference with the Governor of Upper Austria Mag. Thomas Stelzer and the Provincial Minister for Economics and Research Markus Achleitner.